Product Development Process Plastic Moulding

Product Development Process: Plastic Moulding

Rigorous material analysis and quality checks ensure only the finest raw materials are used.

Advanced machinery shapes molten plastic into precise, consistent parts with zero tolerance for error.

Manual finishing removes excess flash for smooth, clean edges and superior surface finish.

Each component is measured and inspected using digital tools to meet exact dimensional standards.

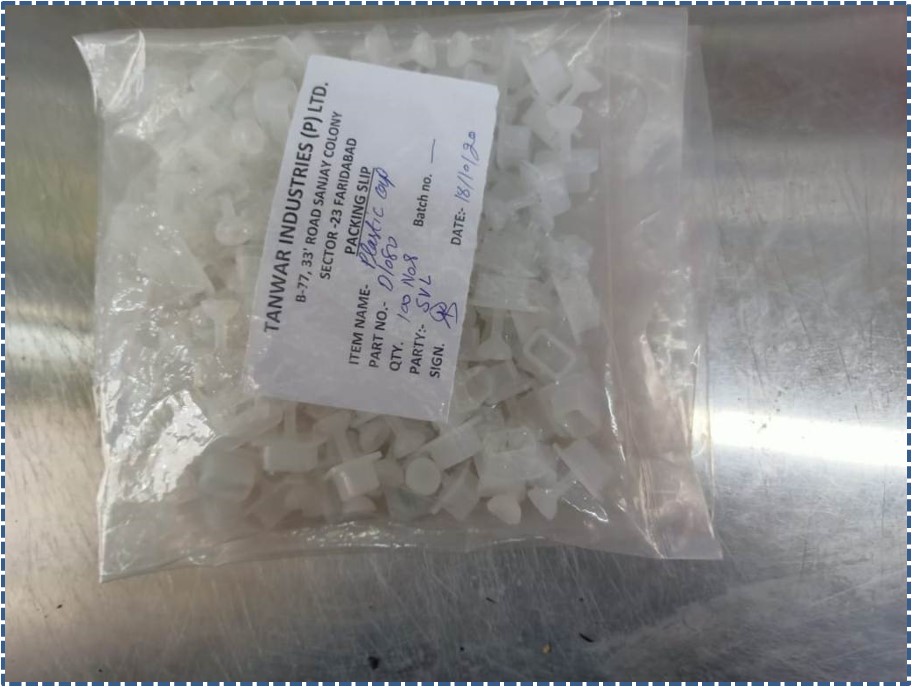

Carefully packed and labeled for safe delivery — ready for integration into your final product.